Application: In Industrial Construction, Machinery/Rack/Container manufacturing

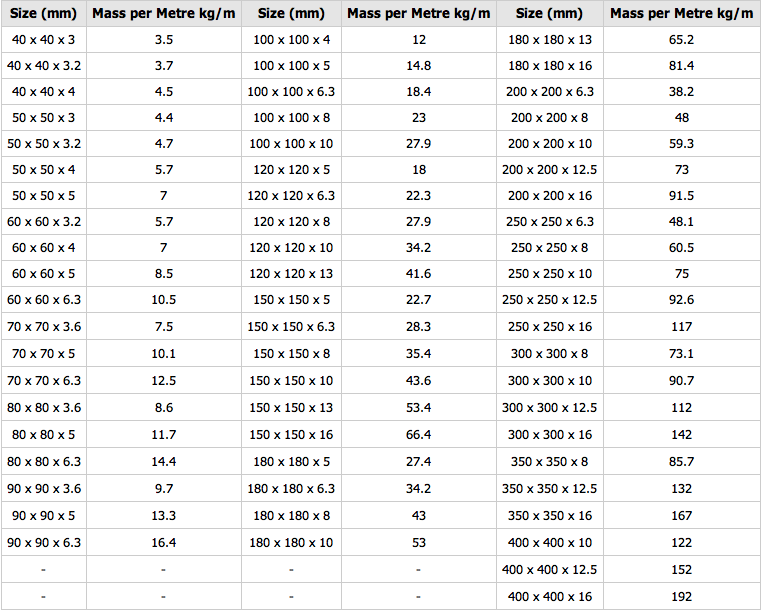

Specification: OD: 10mm*10mm ~ 500mm*500mm

WT: 0.5mm ~ 20mm

LENGTH: 0.3mtr ~ 18mtr

Standard: ASTM A500, ASTM A53, EN 10210, EN 10219, JIS G 3466, BS 1387, BS 6323.

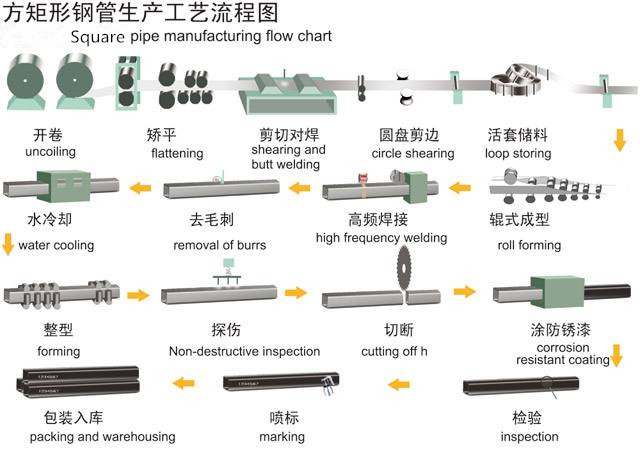

Process Type: Hot Rolled/Hot Expanded, Electric Resistance/High Frequency

End: Square Cut, Burr Removed

Surface: Bare, Black Painting, Lightly Oiled, Galvanized

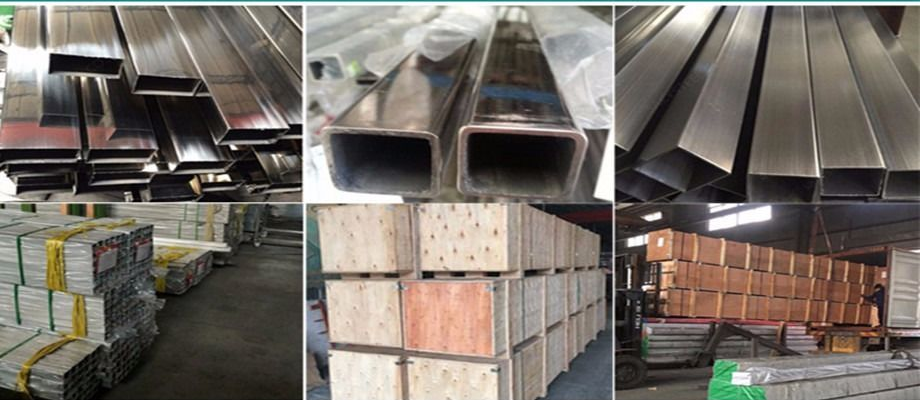

Packing: Waterproof Paper Wrapped, Steel Strips Bundled, Two Tags on Each Bundle

For details, delivery time and prices, please mail us

Production Process of Square Tubes

Specification of Square Tubes

Technical Datas of Square Tubes

STRUCTURAL SQUARE AND RECTANGULAR TUBING TOLERANCES

(ASTM A-500 GRADES A,B,C AND D)

Mechanical Properties

ASTM A500

Grade A

Grade B

Grade C

Grade D

Tensile Strength (min. PSI)

45,000

58,000

62,000

58,000

Yield Strength (min. PSI)

39,000

46,000

50,000

36,000

Elongation in 2 inch (min. %)

25*

23**

21***

23**

* Applies to specified wall thicknesses (t) equal to or greater than 0.120". For lighter specified wall thicknesses, the minimum elongation values shall be calculated by the formula: % elongation in 2" = 56t+17.5 , rounded to the nearest percent.

** Applies to specified wall thicknesses (t) equal to or greater than 0.180". For lighter specified wall thicknesses, the minimum elongation values shall be calculated by the formula: % elongation in 2" = 61t+12 , rounded to the nearest percent.

*** Applies to specified wall thicknesses (t) equal to or greater than 0.120". For lighter specified wall thicknesses, the minimum elongation values shall be by agreement with the manufacturer.

| Typical Chemical Composition | ||||

| Chemistry (%) | ASTM A500 | |||

| Grades A, B, & D | Grade C | |||

| Heat Analysis | Product Analysis | Heat Analysis | Product Analysis | |

| Carbon* | 0.26 Max | 0.30 Max | 0.23 Max | 0.27 Max |

| Manganese* | 1.35 Max | 1.40 Max | 1.35 Max | 1.40 Max |

| Phosporus | 0.035 Max | 0.045 Max | 0.035 Max | 0.045 Max |

| Sulphur | 0.035 Max | 0.045 Max | 0.035 Max | 0.045 Max |

| Copper** | 0.20 Min | 0.18 Min | 0.20 Min | 0.18 Min |

| * For each reduction of 0.01 percentage point below the specified maximum for carbon, an increase of 0.06 percentage point above the specified maximum for manganese is permitted, up to a maximum of 1.50% by heat analysis and 1.60% by product analysis. | ||||

| **If copper containing steel is specified in the purchase order | ||||

Surface of Square Tubes

Bare, Black Painting, Lightly Oiled, Galvanized

Packing of Square Tubes

Product Advantages of Square Tubes

Square Tubes are commonly used for industrial purposes as it can provide numerous benefits. Industries value square tubing for its strength and ability to withstand extremes of temperature, pressure and destructive elements. While in domestic settings, square tubes are used in appliances, pipes, and fencing. Here are just a few of the many benefits and applications of square tubing.

Benefits of Square Tubing

1 Uniformity

Besides its mechanical properties, square tubing contains uniform wall thickness and concentricity.

2 Strength

Cold forming allows square tubing to have a higher yield and tensile strength than the steel from which it is made. This makes the material able to withstand extreme temperatures, pressures, and destructive elements.

3 Cost-Effectiveness

Square tubing undergoes less processing than other types of mechanical tubing, so it can provide cost advantages for less-demanding applications.

4 Wide Range in Sizes

Square tubing is available in an exceptionally broad range of OD and wall thickness dimensions. This makes it suitable for various applications and needs.

We stocks carbon steel square tubing in A513 (mechanical) and A500 (structural) grades, in a range of sizes and wall thicknesses. A500 structural carbon square tube is used in construction, buildings, towers, and sign support applications, but also in trailers and structural fabrications. A513 mechanical carbon steel square tube is frequently used in the automotive, solar, appliance, and agriculture industries, as well as in many other types of machinery ranging from bases to supports.

All ODs below 2" with wall thickness less than 0.120 inch are typically manufactured as ASTM A-513. Sizes 2" and above with wall thickness of 0.120 inch and heavier are typically manufactured to ASTM A-500.