Pipe Type: Structural Pipe, Structural Seamless Pipe, Seamless Structural Pipe

Application: In Structural Engineering and Construction Industry

Specification: OD: 1/8'' ~ 26'' (10.3 ~ 660mm)

WT: SCH 10 ~ 160, SCH STD, SCH XS, SCH XXS

LENGTH: Fixed Length (5.8/6/11.8/12mtr), SRL, DRL

Standard: ASTM A53/A252/A500/A501, JIS G3444, EN 10210/10219

Ends: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

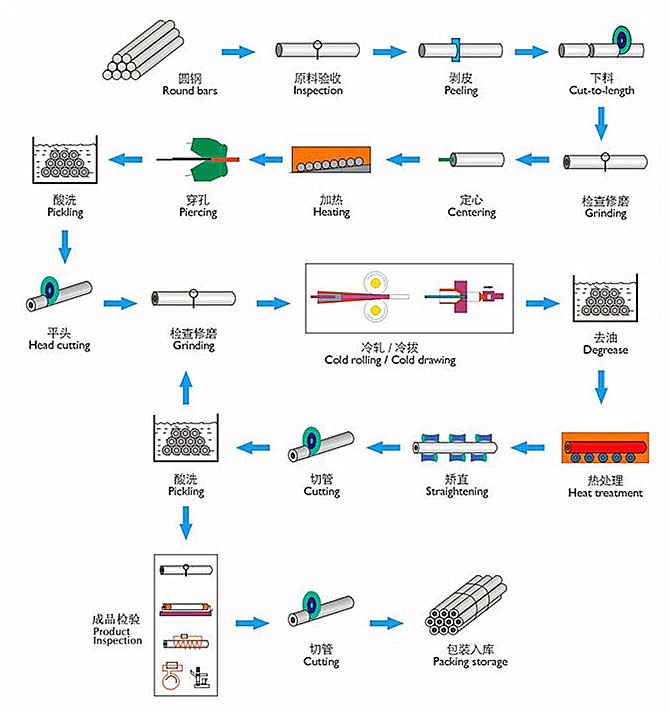

Structural Steel Pipe Manufacturing Process

Specification of Structural Steel Pipe

| API 5L/ASTM A106 GR.B, Structural Steel Pipe | ||||

|

公称通径 DN |

外径OD(mm) | SCH40(6m/5.8m) | SCH40(6m/5.8m) | SCH40(6m/5.8m) |

| 壁厚WT | 壁厚WT | 壁厚WT | ||

| (mm) | (mm) | (mm) | ||

| 1/4'' | 13.7 | 2.24 | 3.02 | / |

| 3/8'' | 17.1 | 2.31 | 3.2 | / |

| 1/2'' | 21.3 | 2.77 | 3.73 | 4.78 |

| 3/4'' | 26.7 | 2.87 | 3.91 | 5.56 |

| 1'' | 33.4 | 3.38 | 4.55 | 6.35 |

| 1-1/4'' | 42.2 | 3.56 | 4.85 | 6.35 |

| 1-1/2'' | 48.3 | 3.68 | 5.08 | 7.14 |

| 2'' | 60.3 | 3.91 | 5.54 | 8.74 |

| 2-1/2'' | 73 | 5.16 | 7.01 | 9.53 |

| 3'' | 88.9 | 5.49 | 7.62 | 11.13 |

| 3-1/2'' | 101.6 | 5.74 | 8.08 | / |

| 4'' | 114.3 | 6.02 | 8.56 | 13.49 |

| 5'' | 141.3 | 6.55 | 9.53 | 15.88 |

| 6'' | 168.3 | 7.11 | 10.97 | 18.26 |

| 8'' | 219.1 | 8.18 | 12.7 | 23.01 |

| 10'' | 273 | 9.27 | 15.09 | 28.58 |

| 12'' | 323.8 | 10.31 | 17.48 | 33.32 |

| 14'' | 355.6 | 9.53 | 11.13 | 19.05 |

| 16'' | 406.4 | 9.53 | 12.7 | 21.44 |

| 18'' | 457 | 9.53 | 14.27 | 23.83 |

| 20'' | 508 | 9.53 | 15.09 | 26.19 |

| 24'' | 610 | 9.53 | 17.48 | 30.96 |

Structural Steel Pipe Chemical Composition and Mechanical Properties

| Standard | Grade |

Chemical Composition (%) |

Mechanical Properties |

||||||

| ASTM A53 |

C |

Si |

Mn |

P |

S |

Tensile STrength(Mpa) |

Yield STrength(Mpa) |

||

| A |

≤0.25 |

- |

≤0.95 |

≤0.05 |

≤0.06 |

≥330 |

≥205 |

||

| B |

≤0.30 |

- |

≤1.2 |

≤0.05 |

≤0.06 |

≥415 |

≥240 |

||

| ASTM A106 |

A |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥415 |

≥240 |

|

|

B |

≤0.35 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥485 |

≥275 |

||

| ASTM A179 | A179 |

0.06-0.18 |

- |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

| ASTM A192 | A192 |

0.06-0.18 |

≤0.25 |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

| API 5L PSL1 | A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

≥331 |

≥207 |

|

|

B |

0.28 |

- | 1.20 |

0.030 |

0.030 |

≥414 |

≥241 |

||

|

X42 |

0.28 |

- | 1.30 |

0.030 |

0.030 |

≥414 |

≥290 |

||

|

X46 |

0.28 |

- | 1.40 |

0.030 |

0.030 |

≥434 |

≥317 |

||

|

X52 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥455 |

≥359 |

||

|

X56 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥490 |

≥386 | ||

|

X60 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥517 |

≥448 | ||

|

X65 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥531 |

≥448 | ||

|

X70 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥565 |

≥483 |

||

| API 5L PSL2 |

B |

0.24 |

- |

1.20 |

0.025 |

0.015 |

≥414 |

≥241 |

|

|

X42 |

0.24 |

- |

1.30 |

0.025 |

0.015 |

≥414 |

≥290 |

||

|

X46 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥434 |

≥317 |

||

|

X52 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥455 |

≥359 |

||

|

X56 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥490 |

≥386 |

||

|

X60 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥517 |

≥414 |

||

|

X65 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥531 |

≥448 |

||

|

X70 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥565 |

≥483 |

||

|

X80 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥621 |

≥552 | ||

Structural Steel Pipe Chemical Composition and Mechanical Properties

|

Standard |

Grade |

Chemical Composition |

Mechanical Properties |

|||||||||

|

C |

Si |

Mn |

P | S |

Cr |

Ni |

Cu |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

Elongation(%) |

||

|

GB/T8163 |

10 |

0.07-0.14 |

0.17-0.37 |

0.35-0.65 |

≤0.035 |

≤0.035 |

≤0.15 |

≤0.25 |

≤0.25 |

335-457 |

≥205 |

≥24 |

| 20 |

0.17-0.24 |

0.17-0.37 |

0.35-0.65 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

≤0.25 |

410-550 |

≥245 |

≥20 |

|

|

Q345 |

0.12-0.20 |

0.20-0.55 |

1.20-1.60 |

≤0.045 |

≤0.045 |

- | - | - |

490-665 |

≥325 |

≥21 | |

|

Pipe types |

Pipe Szie(mm) |

Tolerances |

|

|

Hot rolled |

OD |

All |

±1% (min ±0.50mm) |

|

WT |

All |

+15%, -12.5% |

|

|

Cold drawn |

OD |

6~10 |

±0.20mm |

|

10~30 |

±0.40mm |

||

|

30~50 |

±0.45mm |

||

|

>50 |

±1% |

||

| WT |

≤1 |

±0.15mm |

|

|

>1~3 |

+15% -10% |

||

|

>3 |

+12.5% -10% | ||

| Plain End | Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Plain End (Square Cut) | Wall Thickness over 0.5 inch, including SCH XXS |

| Beveled End |

Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Couplings | Outside Diameter equal or less than 2'' |

| Thread Protection | Outside Diameter over 4 inch |

Surface of Structural Steel Pipe

Bare, Lightlyed, Black/Re Oild/Yellow Painting, Zinc/Anti-corrosive Coating

Packing of Structural Steel Pipe

Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Product Advantages of Structural Steel Pipe

We can produce all sizes of structural pipes, according to European, Chinese, American, Japanese standard. With fast delivery time, supportive payment term.

All tubes production processes are controlled strictly, with high level of quality requirement, all tubes are inspection before delivery, and also accept third party inspection before delivery.

| Types | Application |

|

Structure Purposes |

General structure and mechanical |

|

Liquid Services |

Petroleum, gas and other fluids conveying |

|

Low and Medium Pressure |

Steam and boiler manufacturing |

|

Hydraulic Pillar Service |

Hydraulic support |

|

Auto Semi-shaft Casing |

Auto sem-shaft casing |

|

Line Pipe |

Oil and gas conveying |

|

Tubing and Casing |

Oil and gas conveying |

|

Drill Pipes |

Well drilling |

|

Geological Drilling Pipe |

Geological drilling |

|

Petroleum Cracking Tubes |

Furnace tubes, heat exchangers |