Application: Used as the Structural Retainer for the Walls of Oil, Gas Wells

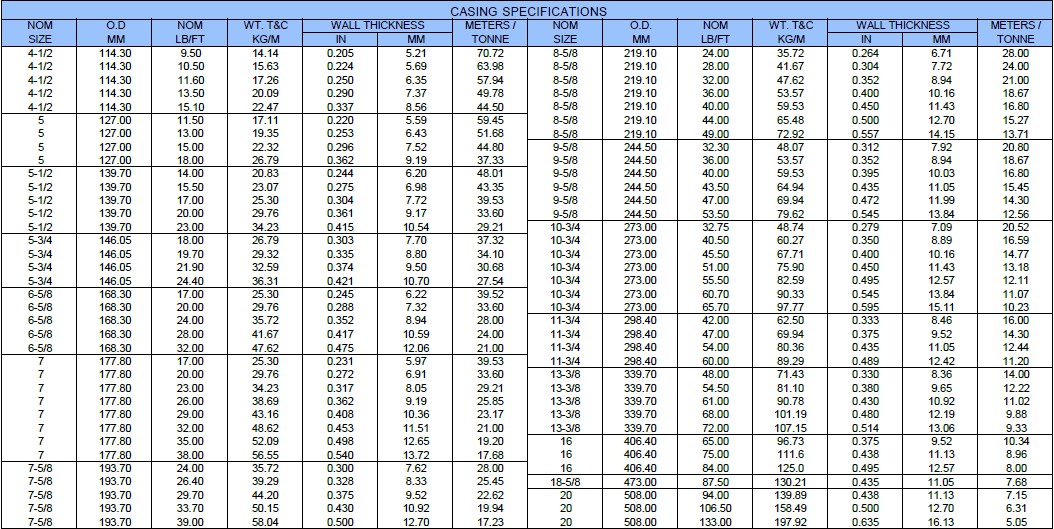

Specification: OD: 4 1/2’’ ~ 20’’ (114.3mm ~ 508mm)

WT: 0.205’’ ~ 0.635’’ (5.21mm ~ 16.13mm)

LENGTH: R1, R2, R3

Standard: API 5CT J55/K55/N80/C75/L80/C90/T95/Q125

Process Type: Seamless (SMLS), Electric Resistance Welded (ERW)

End: Beveled, Square Cut, With LTC/STC/BTC/VAM Connection

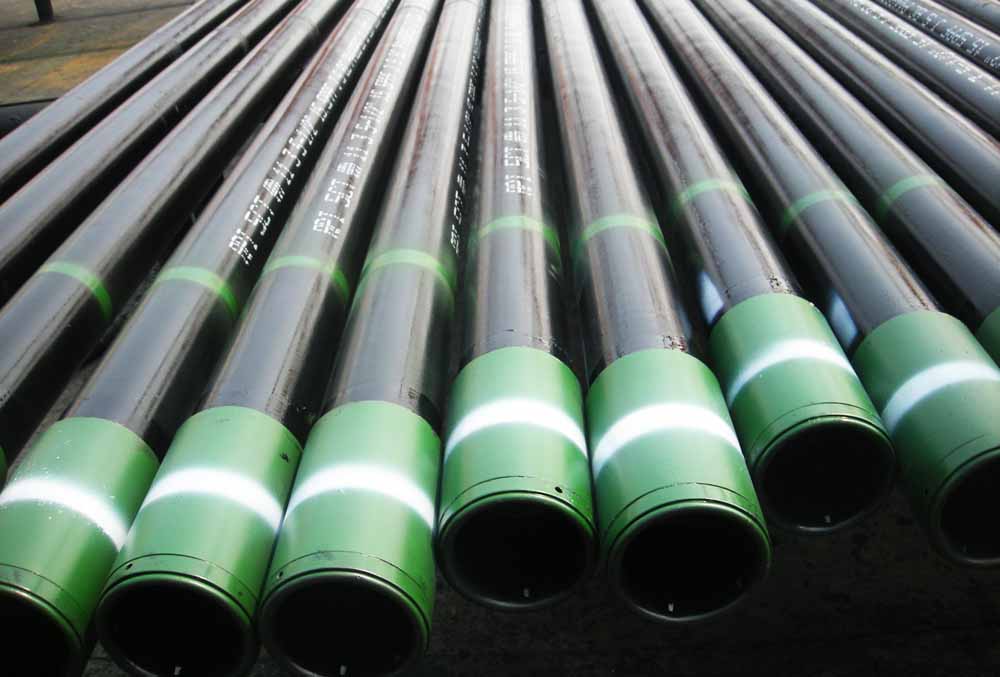

Surface: Anti-corrosion&water Based Paint

Packing: Protection Caps in Both Ends, Waterproof Paper Wrapped, Two Tags

For details, delivery time and prices, please mail us

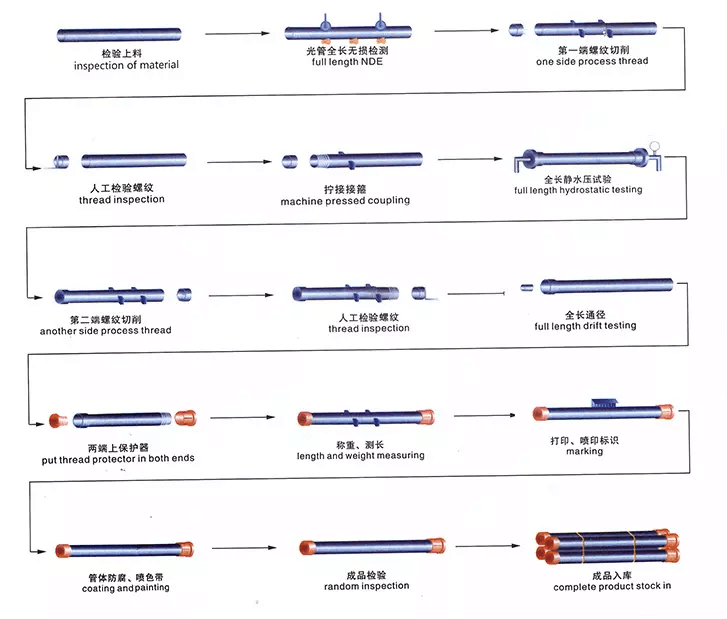

Production Process of API Casing Steel Pipe

Process of API Casing Steel Pipe

Specification of API Casing Steel Pipe

|

Types of steel tubes |

Outer Diameter |

Wall Thickness |

|

|

Cold-rolled tubes |

Tube sizes(mm) |

Tolerances(mm) |

Tolerances(mm) |

|

<114.3 |

±0.79 |

-12.5% | |

Technical Datas of API Casing Steel Pipe

Chemical Composition

| Standard | Grade |

Chemical compositions(%) |

|||||||||

|

API SPEC 5CT |

J55 |

C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ | / | |

|

N80 |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ | / | / |

0.11~0.16 |

|

|

L80 |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ | / | |

|

P110 |

0.26~0.395 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0.08 | |

| Grade | Type |

Total elongation under load (%) |

Yield strength (min) |

Yield strength (max) |

Tensile strength min Mpa |

Hardness Max (HRC) |

Hardness Max(HBW) |

| J55 | - |

0.5 |

379 | 552 | 517 | - | - |

| K55 | - |

0.5 |

379 | 552 | 655 | - | - |

| N80 | 1 |

0.5 |

552 | 758 | 689 | - | - |

| N80 | Q |

0.5 |

552 | 758 | 689 | - | - |

| L80 | 1 |

0.5 |

552 | 655 | 655 | 23 | 241 |

|

L80 |

9Cr |

0.5 |

552 | 655 | 655 | 23 | 241 |

|

L80 |

13Cr |

0.5 |

552 | 655 | 655 | 23 | 241 |

| C90 | - |

0.5 |

621 | 724 | 689 | 25.4 | 255 |

| C95 | - |

0.5 |

655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | All | 0.65 | 862 | 1034 | 931 | - | - |

Surface of API Casing Steel Pipe

Anti-corrosion Water Based Paint

Packing of API Casing Steel Pipe