Pipe Type: Seamless Pipe, Seamless Carbon Steel Pipe, Carbon Steel Seamless Pipe, Hot Rolled Seamless Steel Pipe, Cold Drawn Seamless Steel Pipe, Cold Rolled Seamless Steel Pipe

Application: For High Temperature Service, High Temperature Fluids Transmission (oil, gas, water, steam etc.)

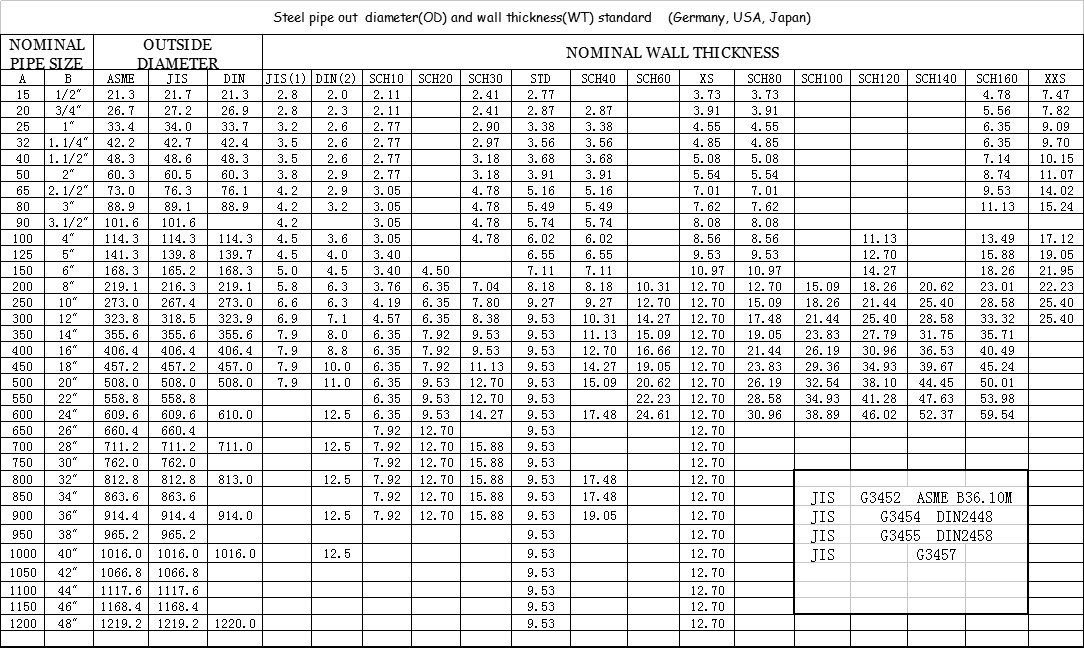

Specification: OD: 1/8'' ~ 48'' (10.3 ~ 1219mm)

WT: SCH 10 ~ 160, SCH STD, SCH XS, SCH XXS

LENGTH: Fixed Length (5.8/6/11.8/12mtr), SRL, DRL

Standard & Grade: ASTM A106, Grade A/B/C

Ends: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

For details, delivery time and prices, please mail us

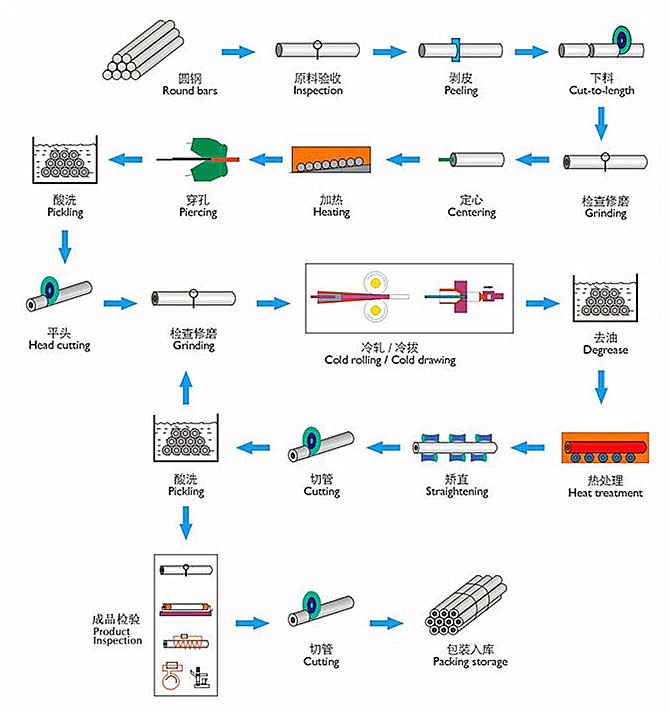

Production Process of Seamless Steel Pipe

Mandrel Mill Process

In the Mandrel Mill Process, a solid round (billet) is used. It is heated in a rotary hearth heating furnace and then pierced by a piercer. The pierced billet or hollow shell is rolled by a mandrel mill to reduce the outside diameter and wall thickness which forms a multiple length mother tube. The mother tube is reheated and further reduced to specified dimensions by the stretch reducer. The tube is then cooled, cut, straightened and subjected to finishing and inspection processes befor shipment.

Mannesmann plug mill process

In the Plug Mill Process, a solid round (billet) is used. It is uniformly heated in the rotary hearth heating furnace and then pierced by a Mannesmann piercer. The pierced billet or hollow shell is rollreduced in outside diameter and wall thickness. The rolled tube simultaneously burnished inside and outside by a reeling machine. The reeled tube is then sized by a sizing mill to the specified dimensions. From this step the tube goes through the straightener. This process completes the hot working of the tube. The tube (referred to as a mother tube) after finishing and inspection, becomes a finished product.

Specification of Seamless Steel Pipe

This specification covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. The pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. All seamless and welded pipes shall be treated to control their micro-structure. Tensile tests, impact tests, hydro-static tests, and nondestructive electric tests shall be made in accordance to specified requirements.

1. Scope

1.1 This specification covers nominal (average) wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. Several grades of ferric steel are included as listed in Table 1. Some product sizes may not be available under this specification because heavier wall thicknesses have an adverse affect on low-temperature impact properties.

1.2 Supplementary Requirement S1 of an optional nature is provided. This shall apply only when specified by the purchaser.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in non-conformance with the specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

Seamless Steel Pipe Chemical Composition and Mechanical Properties

This data is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

| Standard | Grade |

Chemical Composition (%) |

Mechanical Properties |

||||||

| ASTM A53 |

C |

Si |

Mn |

P |

S |

Tensile STrength(Mpa) |

Yield STrength(Mpa) |

||

| A |

≤0.25 |

- |

≤0.95 |

≤0.05 |

≤0.06 |

≥330 |

≥205 |

||

| B |

≤0.30 |

- |

≤1.2 |

≤0.05 |

≤0.06 |

≥415 |

≥240 |

||

| ASTM A106 |

A |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥415 |

≥240 |

|

|

B |

≤0.35 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥485 |

≥275 |

||

| ASTM A179 | A179 |

0.06-0.18 |

- |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

| ASTM A192 | A192 |

0.06-0.18 |

≤0.25 |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

| API 5L PSL1 | A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

≥331 |

≥207 |

|

|

B |

0.28 |

- | 1.20 |

0.030 |

0.030 |

≥414 |

≥241 |

||

|

X42 |

0.28 |

- | 1.30 |

0.030 |

0.030 |

≥414 |

≥290 |

||

|

X46 |

0.28 |

- | 1.40 |

0.030 |

0.030 |

≥434 |

≥317 |

||

|

X52 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥455 |

≥359 |

||

|

X56 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥490 |

≥386 | ||

|

X60 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥517 |

≥448 | ||

|

X65 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥531 |

≥448 | ||

|

X70 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥565 |

≥483 |

||

| API 5L PSL2 |

B |

0.24 |

- |

1.20 |

0.025 |

0.015 |

≥414 |

≥241 |

|

|

X42 |

0.24 |

- |

1.30 |

0.025 |

0.015 |

≥414 |

≥290 |

||

|

X46 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥434 |

≥317 |

||

|

X52 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥455 |

≥359 |

||

|

X56 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥490 |

≥386 |

||

|

X60 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥517 |

≥414 |

||

|

X65 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥531 |

≥448 |

||

|

X70 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥565 |

≥483 |

||

|

X80 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥621 |

≥552 | ||

Carbon Steel Seamless Pipe Chemical Composition and Mechanical Properties

|

Standard |

Grade |

Chemical Composition |

Mechanical Properties |

|||||||||

|

C |

Si |

Mn |

P | S |

Cr |

Ni |

Cu |

Tensile Strength(Mpa) |

Yield Strength(Mpa) |

Elongation(%) |

||

|

GB/T8163 |

10 |

0.07-0.14 |

0.17-0.37 |

0.35-0.65 |

≤0.035 |

≤0.035 |

≤0.15 |

≤0.25 |

≤0.25 |

335-457 |

≥205 |

≥24 |

| 20 |

0.17-0.24 |

0.17-0.37 |

0.35-0.65 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

≤0.25 |

410-550 |

≥245 |

≥20 |

|

|

Q345 |

0.12-0.20 |

0.20-0.55 |

1.20-1.60 |

≤0.045 |

≤0.045 |

- | - | - |

490-665 |

≥325 |

≥21 | |

|

Pipe types |

Pipe Szie(mm) |

Tolerances |

|

|

Hot rolled |

OD |

All |

±1% (min ±0.50mm) |

|

WT |

All |

+15%, -12.5% |

|

|

Cold drawn |

OD |

6~10 |

±0.20mm |

|

10~30 |

±0.40mm |

||

|

30~50 |

±0.45mm |

||

|

>50 |

±1% |

||

| WT |

≤1 |

±0.15mm |

|

|

>1~3 |

+15% -10% |

||

|

>3 |

+12.5% -10% | ||

| Plain End | Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Plain End (Square Cut) | Wall Thickness over 0.5 inch, including SCH XXS |

| Beveled End |

Wall Thickness less than 0.5 inch, including SCH STD & SCH XS |

| Couplings | Outside Diameter equal or less than 2'' |

| Thread Protection | Outside Diameter over 4 inch |

Surface of Seamless Steel Pipe

Surface treatment is the impact on the life of the coating, dominating, pipe coating and decided to extend the life of the seamless steel pipe is subjected to surface treatment, it should continue to improve seamless steel surface treatment.

Surface strength seamless steel pipe, the surface roughness of the original rust into a degree, abrasive coating material to choose, in order to achieve better results, as well as the role of grit etched steel surface, has strengthened steel shot the role of steel surface, mixing abrasive steel shot and grit, for it can be a single layer of epoxy easier to achieve the desired effect.

Seamless tube, before the outer wall surface rust should be pre-treated, the outer surface of the grease, dirt, debris clean, ensure inner and outer walls smooth surface. Inner and outer walls after cleared, artificial rust, rust and iron oxide to the outer surface of the cleaned metal surface rust treatment to meet the requirements grade standards. Seized by rust after passing inspection, should be within 8 hours of brushing the primer. In case of bad atmospheric environment (such as high humidity, salt spray containing air), should further shorten the time.Pipeline corrosion paint brush, depending on the nature of the anti-corrosion paint, paint a good tune, with soft and hard appropriate brush dipped in paint brush pipe surface. Brushing force uniform, kicked around, there should be flowing and piled brush and leakage phenomenon. Anti-corrosion coating paint brush to be divided over the conduct, and so again before the paint dry and then brushing the next pass.

There abrasive roughness is too easy to Cao coating thin, because too deep anchor pattern will form bubbles in the corrosion process, thereby seriously affecting the performance of the coating, such as roughness is too small, it will lead coating impact strength decreased adhesion, if you want to rely on the cleaning effect of small particles polished off corrosion products, not only to improve the utilization of the abrasive but also slow down the pipes and nozzles .

Packing of Seamless Steel Pipe

Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Product Advantages of Seamless Steel Pipe

1.The greatest advantage of seamless steel pipes is their increased ability to withstand pressure. The weakest point in a welded steel pipe is the welded seam. But because a seamless steel pipe has not been welded, it doesn’t have that seam, making it equally strong around the entire circumference of the pipe.

2.Because welded seam pipe is wrapped around another form before it is welded, and because welding adds heat, stress and other extraneous variables to the forming process, it can never be as round as seamless steel pipe.

3.Seamless steel pipe can sometimes be more expensive than other forms of steel pipe, but it’s also more reliable.

Seamless Steel Pipe Classification and Application

| Types | Application |

|

Structure Purposes |

General structure and mechanical |

|

Liquid Services |

Petroleum, gas and other fluids conveying |

|

Low and Medium Pressure |

Steam and boiler manufacturing |

|

Hydraulic Pillar Service |

Hydraulic support |

|

Auto Semi-shaft Casing |

Auto sem-shaft casing |

|

Line Pipe |

Oil and gas conveying |

|

Tubing and Casing |

Oil and gas conveying |

|

Drill Pipes |

Well drilling |

|

Geological Drilling Pipe |

Geological drilling |

|

Petroleum Cracking Tubes |

Furnace tubes, heat exchangers |