Pipe Type: SSAW Pipe, SSAW Steel Pipe, Spiral Steel Pipe, Welded Spiral Pipe

Application: For Ordinary Structural Support (well casing, bridge, building, pile driving)

Specification: OD: 219.1mm ~ 3500mm

WT: 6mm ~ 25mm (Up to 1'')

LENGTH: 6mtr ~ 18mtr, SRL, DRL

Standard & Grade: ASTM A252 Grade 1/2/3

End: Beveled, Square Cut, With LTC/STC/BTC/VAM Connection

Surface: Bare, Lightly Oiling, Black Painting, Anti-corrosion coating(FBE/2PE/3PE)

Packing: Packed In Bulk, Ends Protector on both sides, Waterproof Materials Wrapped

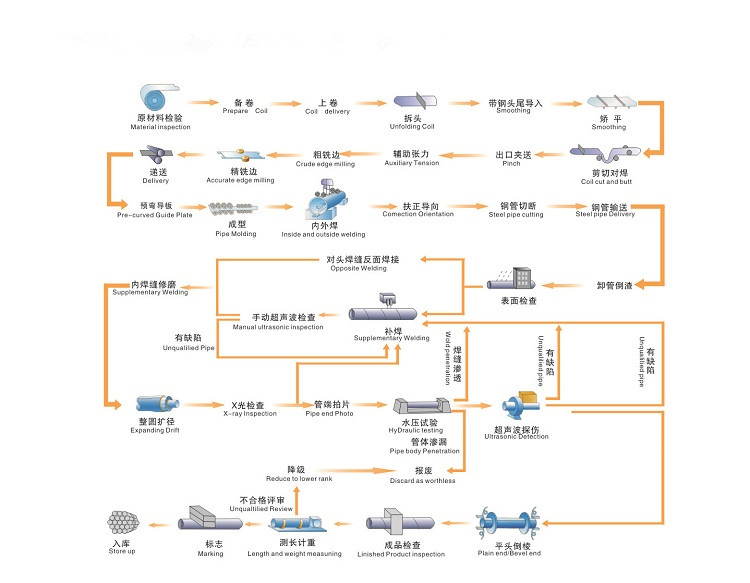

Production Process of Piling Pipe

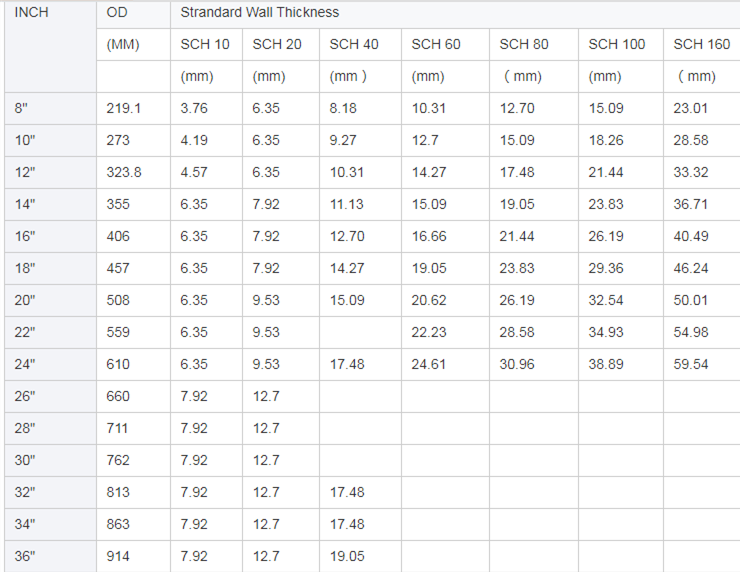

Specification of Piling Pipe

Technical Data of Piling Pipe

Surface of Piling Pipe

Surface: Bare, Lightly Oiling, Black Painting, Anti-corrosion coating(FBE/2PE/3PE)

Packing of Piling Pipe

Packed In Bulk, Ends Protector on both sides, Waterproof Materials Wrapped

Product Advantages of Piling Pipe

As mentioned above, pipe piles can be adjusted to fit the exact load specifications of your project. This means you don’t have to spend extra on structural support, effectively minimizing costs. In addition, replacing pipes is less expensive than alternative piling options, such as sheet or concrete piling.