Application: Used for Well Drilling

Specification: OD: 60.32mm ~ 168.28mm

WT: 7.11mm ~ 9.19mm

LENGTH: R1, R2, R3

Standard: API 5DP E75/X 95/G 105/S 135

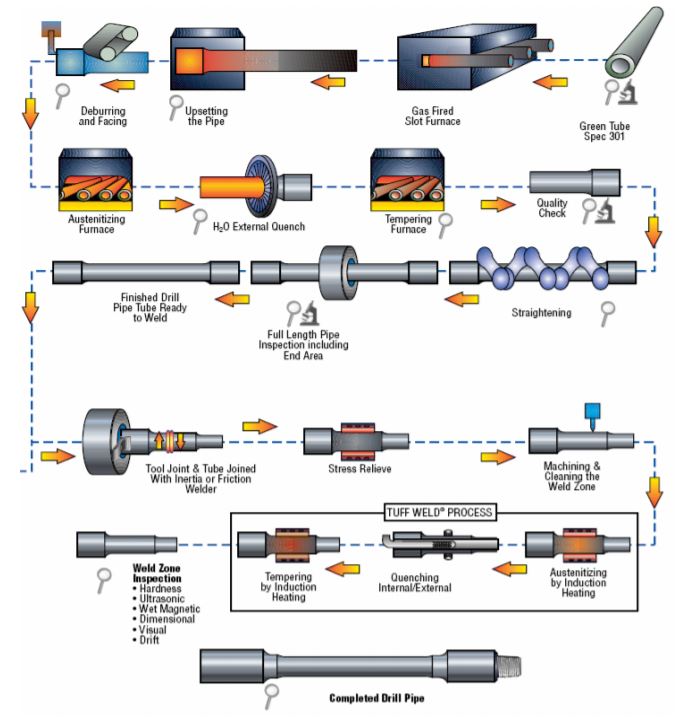

Process Type: Seamless (SMLS), Electric Resistance Welded (ERW)

End: Thread, NC, IF, FH, REG

Surface: Anti-corrosion&water Based Paint

Packing: Protection Caps in Both End, Waterproof Paper Wrapped, Two Tags

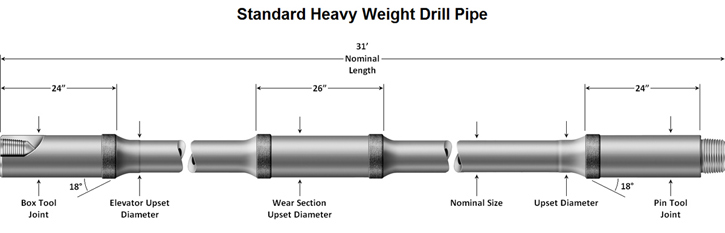

Drill pipes are steel tubulars fitted with threaded ends called tool joints, which are commonly used in tension in the top part of the drill string to pump fluid and transmit torque to the bit.

Standard: Drill pipe

Grade: E75, X95, G105, S135 .

The wear-resistant belt of tool joint: Arnco 100XT, 200XT, 300XT, 400XT

Internal coating drill pipe: TK34, DPC, TC2000, TC3000

Usage: Mine blasting, water well drilling, geothermal wells drilling, fore poling, coal and nonferrous metal mining projects, etc.

Dimension:

Size designation

Calculated weight

Tool joint designation

Calculated weight

grade

Wall thickness

Upset ends

in

1b/ft

Kg/m

in

mm

2 3/8

6.65

NC26

6.26

9.32

E.X.G.S

0.28

7.11

EU

2 7/8

10.4

NC31

9.72

14.48

E.X.G.S

0.362

9.19

EU

3 1/2

13.3

NC38

12.31

18.34

E.X.G.S

0.368

9.35

EU

3 1/2

15.5

NC38,NC40

14.63

21.79

E.X.G.S

0.449

11.4

EU

4

14

NC40,NC46

12.93

19.26

E.X.G.S

0.33

8.38

IU,EU

4 1/2

16.6

NC46,NC50

14.98

22.31

E.X.G.S

0.337

8.56

EU,IEU

4 1/2

20

NC46,NC50

18.69

27.84

E.X.G.S

0.43

10.92

EU,IEU

5

19.5

NC50,NC52

17.93

26.71

E.X.G.S

0.362

9.19

IEU

5

25.6

NC50,5 1/2FH

24.03

35.79

E.X.G.S

0.5

12.7

IEU

5 1/2

21.9

5 1/2FH

19.81

29.51

E.X.G.S

0.361

9.17

IEU

5 1/2

24.7

5 1/2FH

22.54

33.57

E.X.G.S

0.415

10.54

IEU

6 5/8

25.2

6 5/8FH

22.19

33

E.X.G.S

0.33

8.387

IEU

6 5/8

27.7

6 5/8FH

24.21

41

E.X.G.S

0.362

9.19

IEU

Chemical Composition(%):

|

Grade |

Chemical composition |

|

|

P |

S |

|

|

E75 |

<0.015 |

<0.003 |

|

X95 |

<0.015 |

<0.003 |

|

G105 |

<0.015 |

<0.003 |

|

S135 |

<0.015 |

<0.003 |

|

Tool joint |

<0.015 |

<0.003 |

Mechanical Properties:

| Pipe body | Grade | Yield strength | Tensile strength | Elongation | Hardness | Full size charpy impact test(J) | ||||||

| min | max | min | min | |||||||||

| Psi | MPa | Psi | MPa | Psi | MPa | HBW | HRC | Average | Single | |||

| E75 | 75000 | 517 | 105000 | 724 | 100000 | 689 | 625000A0.2/U0.9 | - | - | 80 | 65 | |

| X95 | 95000 | 655 | 125000 | 862 | 105000 | 724 | - | - | 80 | 65 | ||

| G105 | 105000 | 724 | 135000 | 931 | 115000 | 793 | - | - | 80 | 65 | ||

| S135 | 135000 | 931 | 165000 | 1138 | 145000 | 1000 | - | - | 80 | 65 | ||

| Weld zone | Tool joint | 120000 | 827.4 | - | - | 140000 | 965.3 | 0.13 | 285 | - | 80 | 65 |

| E75 | 75000 | 517 | - | - | 100000 | 689 | - | 37 | 40 | 27 | ||

| X95 | 88000 | 609 | - | - | 103000 | 712 | - | 37 | 40 | 27 | ||

| G105 | 95000 | 655 | - | - | 105000 | 724 | - | 37 | 40 | 27 | ||

| S135 | 105000 | 724 | - | - | 115000 | 37 | 40 | 27 | ||||

Surface of Drill Pipe

Anti-corrosion&water Based Paint

Packing of Drill Pipe

Protection Caps in Both End, Waterproof Paper Wrapped, Two Tags

Product Advantages of Drill Pipe

1. To reduce tripping time. By using wireline replacement than traditional drill with drill rod from about 5-10 times faster;

2. Save the drill pipe and drill collars related procurement, transportation, inspection, maintenance and replacement costs;

3. Because there is always the wellbore casing, no longer have the time to drill down from the pumping action within the wellbore, the well control situation has improved;

4. Due to the elimination of the drill pipe from the pumping action and bring pressure pulsation;

5. Maintained when the wire rope from under the continuous circulation drill mud, cuttings prevents aggregation also reduces the occurrence of a kick;

6. To improve the return on annular velocity and cleaning the wellbore conditions. When the sleeve is pumped into the mud because of an inner diameter larger than the drill pipe, reducing the hydraulic losses, which can reduce the drilling rig mud pump with power. Mud returns from the annular space between the casing and the borehole wall, since the annulus area is reduced,

improving the return on the speed and improve the drill cuttings taken out of the situation;

7. The size can be reduced rig, the rig structure to simplify and reduce the cost of drilling rig;

8. Rig more lightweight, easy to move and operate. Manual labor and costs are reduced.