Pipe Type: ERW Pipe, ERW Steel Pipe, Electric Resistance Welded Pipe, HFW Steel Pipe, EFW Steel Pipe

Application: For Low Pressure Fluid Transmission, Machinery Manufacturing

Specification: OD: 21.3mm ~ 660mm

WT: 1mm ~ 17.5mm

LENGTH: 0.5mtr ~ 22mtr (5.8/6/11.8/12 meters, SRL, DRL)

Standard & Grade: API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70

ASTM A53, ASTM A500, JIS G3466, ASTM A252, ASTM A178, AN/NZS 1163, AN/NZS 1074, EN10219-1, EN10217-1

End: Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface: Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc Galvanized/Anti-corrosive Coating

Packing: Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

For details, delivery time and prices, please mail us

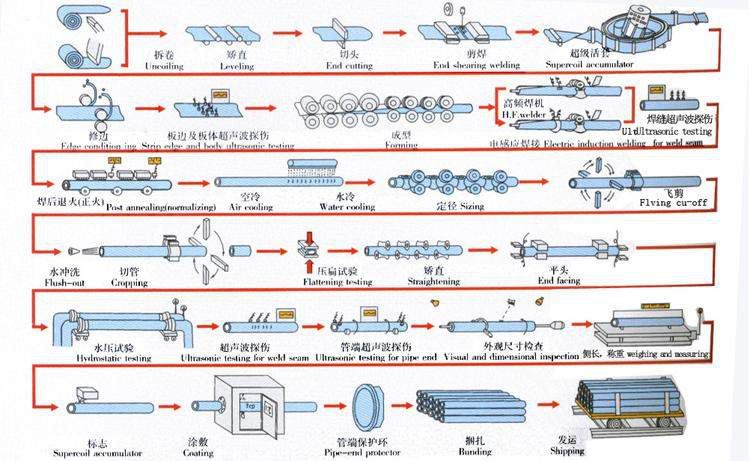

Production Process for ERW Steel Pipe:

1.Uncoiling --- 2. Leveling --- 3. End cutting --- 4. End shearing welding --- 5. Supercoil accumulator --- 6. Edge cutting --- 7. Ultrasonic detection --- 8. Forming --- 9. Electric induction welding --- 10. Ultrasonic detection for weld seam --- 11. Medium frequency heat treatment --- 12. Air cooling --- 13. Water cooling --- 14. Sizing --- 15. Flying cutting --- 16. Flush-out --- 17. Cropping --- 18. Flattening testing --- 19. Straightening --- 20. End facing and bevelling --- 21. Hydrodynamic testing --- 22. Ultrasonic detection for weld seam --- 23. Ultrasonic detection for pipe end --- 24. Visual and dimensions inspection --- 25.Weighting and measuring --- 26. Marking --- 27. Coating --- 28. Pipe-end protection --- 29. Bending --- 30. Shipping

Specification of ERW Steel Pipe:

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tolerance of ERW steel pipe

|

Standard |

Grade |

Out Diameter Tolerance |

Wall Thickness Tolerance |

| ASTM A53 | A | +/-1.0% | +/- 12.5% |

| B | +/- 1.0% | +/- 12.5% |

| Standard |

Grade |

Chemical Analysis(%) |

Mechanical Properties(min)(Mpa) |

||||

| C | Mn | P | S |

Tensile Strength |

Yield Strength |

||

| ASTM A53 | A |

0.25 |

0.95 | 0.05 |

0.045 |

330 |

205 |

| B | 0.30 | 1.20 | 0.05 | 0.045 | 415 |

240 |

|

Surface of ERW Steel Pipe

Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing of ERW Steel Pipe

Bundled/In Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Product Advantages of ERW Steel Pipe

Advantages of erw steel pipe are following below:

F) Longitudinal resistance welded pipe is not welded into the dissimilar metals, but also undergo a rigorous on-line heat treatment, so the basic performance of the weld and material properties.